Returnable packaging in the Rubber Industry

TALKING TO A CUSTOMER ABOUT THE USE OF POOLING SERVICES

It goes without saying that rubber production takes up a substantial part of the total added financial value within EU markets. With nearly 8 thousand of enterprises, and close to 370 thousand of employees in the sector, rubber manufacturing generates nearly 20 billion Euro of turnover (reference Eurostat), which grants the industry a vital place in the European economy.

This being said, consistent supply of raw materials and good quality shipping services are factors of major importance in the manufacturing pipeline. Logistics is an integral process in the context of rubber production. Zamko has provided fitting logistic packaging over the course of 10 years in the marketplace, taking individual manufacturing specifications with seriousness and consideration.

VISITING OUR CLIENT

Recently, we took a short trip to one of our clients’ production sites in Germany, making synthetic rubber, plastic, and polymer raw materials on a large scale. As a returnable packaging provider, we have a duty to have a close-knit relationship and to maintain excellent communication with our partners. We attended a production plant facility where we had the chance to see their working facility and to assess how well was our returnable packaging solution integrated in their manufacturing loop. In the end, we had the chance to have a long chat with the director of logistics operations, who was sharing their experience with us and providing valuable feedback back to our team.

WHY IS RETURNABLE PACKAGING EASY TO IMPLEMENT?

We were sitting comfortably in this big conference room, ornamented with curious rubber tokens, taken from various production lines throughout the years in the making. Over a cup of coffee, we wanted to find out how such a big and successful manufacturer came across our packaging solution and how they will assess the overall implementation of our service.

“Like the majority of synthetic rubber & plastic manufacturers in Europe, we were using traditional one-way packaging to transport our raw materials to customers for many years. In the past, there were no alternatives and we had no other choice but to make big revenue cuts at the end of each year because of the costs of packaging…”

“Technology was advancing, as was our production output, and we needed a better, more sustainable, but also a more practical alternative.”

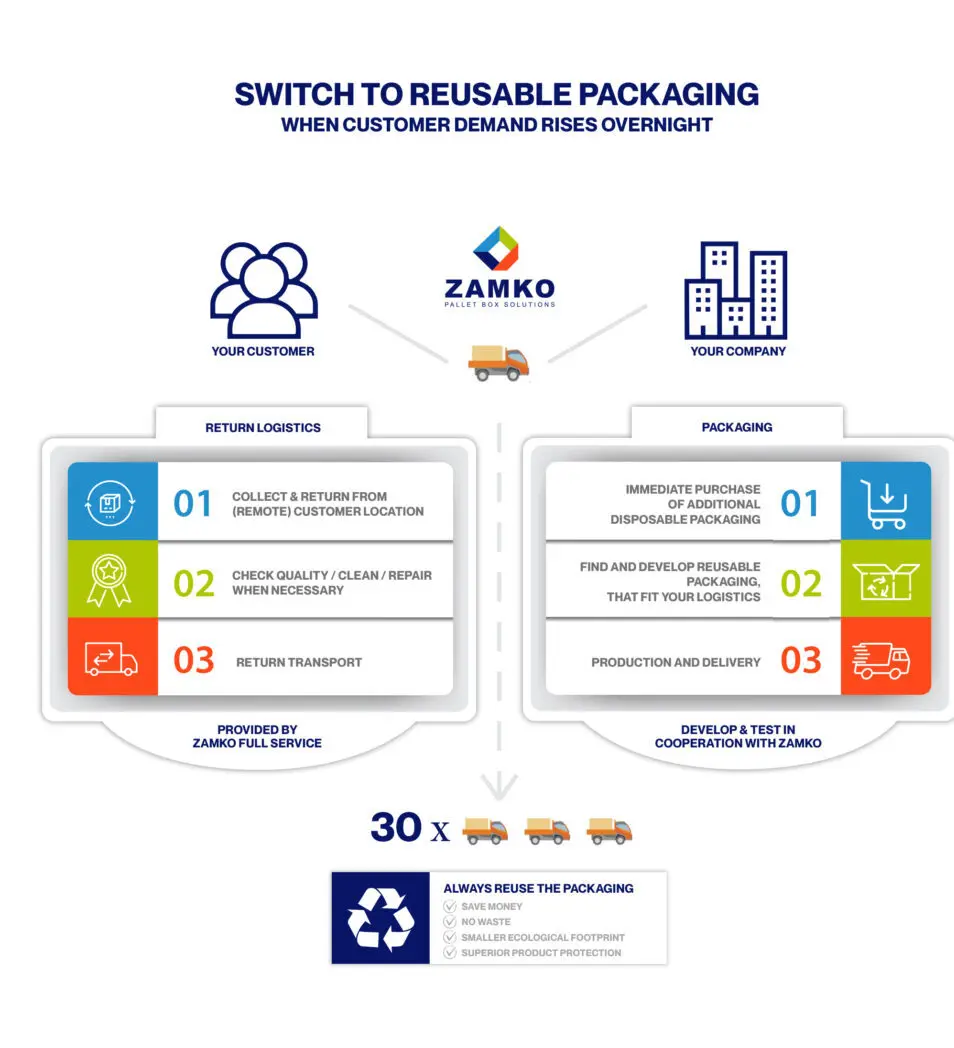

“Zamko was the full pack for us! As a director of logistics, I asked one of my team members to take the lead on this project and find the most efficient and easy-to-implement packaging solutions possible. He came up with several suggestions, and I have to say, your pooling solution had a lot to offer!”

We were curious to know more about how and why they found our service easier to implement than others.

“Well, your customized pallet boxes required no further adjustments from us. When you first sent us the sample design, you had taken care of the whole optimization based on our product specifications. I was impressed by the removable wall, making discharging of our materials easier than ever. Relatively short after our initial correspondence we were ready to transport our first load using your collapsible reusable pallet boxes; they were a perfect fit, and we had no obligation to engage with laborious return processes from our customer. All we needed to do is estimate bulk product quantity for export and pre-order your pallet boxes enough time in advance.”

HOW HASSLE-FREE IS A POOLING PROCESS?

We wanted to know the specifics of their experience with our pooling process, and if the client was experiencing any difficulties with it.

“We are a leading manufacturer of rubber in the country. Logistics is as important to us as the actual production process. Having found Zamko and your pooling solution, not only did we achieve a large cost-cutting, but we also had the chance to focus on our production line and improving our customer relations. Our export logistics was fully outsourced; we were saving both on valuable time resources to do with logistics operations and we were cutting down on typical reductions of deliverable stock to customers (due to damage or contamination).”

“We received a lot of positive feedback from our clients about the high integrity of our rubber loads, which even boosted our sales.”

FINAL WORDS

We asked our client to summarize their experience with us.

“We reduced the product loss on damaged deliveries immensely, increased our profit in a simple way, and achieved higher customer satisfaction. I reckon we will not be changing our packaging solution provider anytime soon…!”

Leave your comment here:

Leave your comment through the form below and share your opinion.

More from the Category

Gain insights by reading our blogs.

Why ZAMKO?

If you’re wondering where to buy pallet boxes, you’ve come to the right place! ZAMKO is a specialist supplier of new and used pallet boxes. Based in The Netherlands, we can deliver high quality boxes on a just in time basis throughout Europe.

Read more about Zamko